Complete Self-Contained Oil Flushing Mobile Unit in Sale

Our Mobile Oil Cleaning & Flushing Machine is designed to go anywhere

The Latest Technology in Oil Flush Services in Victoria

Remote Areas | Victoria-Wide | State-Wide | Global | Off-Shore

Slide title

Write your caption hereButton

Oil Flushing and Filtration Services by Union Hydraulics Pty Ltd

Union Hydraulics Pty Ltd is a leading provider of oil flushing and filtration services in Sale, Victoria. With over 20 years of experience in the oil and gas industry, we have successfully completed an extensive range of oil flushing projects on new installations for many major clients across Australia.

Our team is proud to offer an oil cleaning and decontamination service that includes line flushing. As the years have gone by, we have greatly refined our process, and using the knowledge we have gained, we have designed, developed, and commissioned our very own purpose-built oil flushing and filtration module.

During the design and inception stages of this module, the design team, headed by Denis Lucardie, considered the hurdles we have encountered over the years to design a custom-made unit to negate these issues and improve the process. This, in turn, makes the process more financially viable for the client.

What Is Clean Oil?

The new oil is not clean and does not meet plant and equipment OEM’s clean oil requirements of ISO 4406 and NAS 1638. Flushing of systems and the filtration of first-fill oils will remove all contaminants down to submicron-size particles. This ensures an optimum level of lubrication which will help protect your plant and equipment. Not only will our new oil flushing and filtration module flush your equipment, but it will also ensure oil cleanliness to AS 4059 & NAS1638.

Specifications

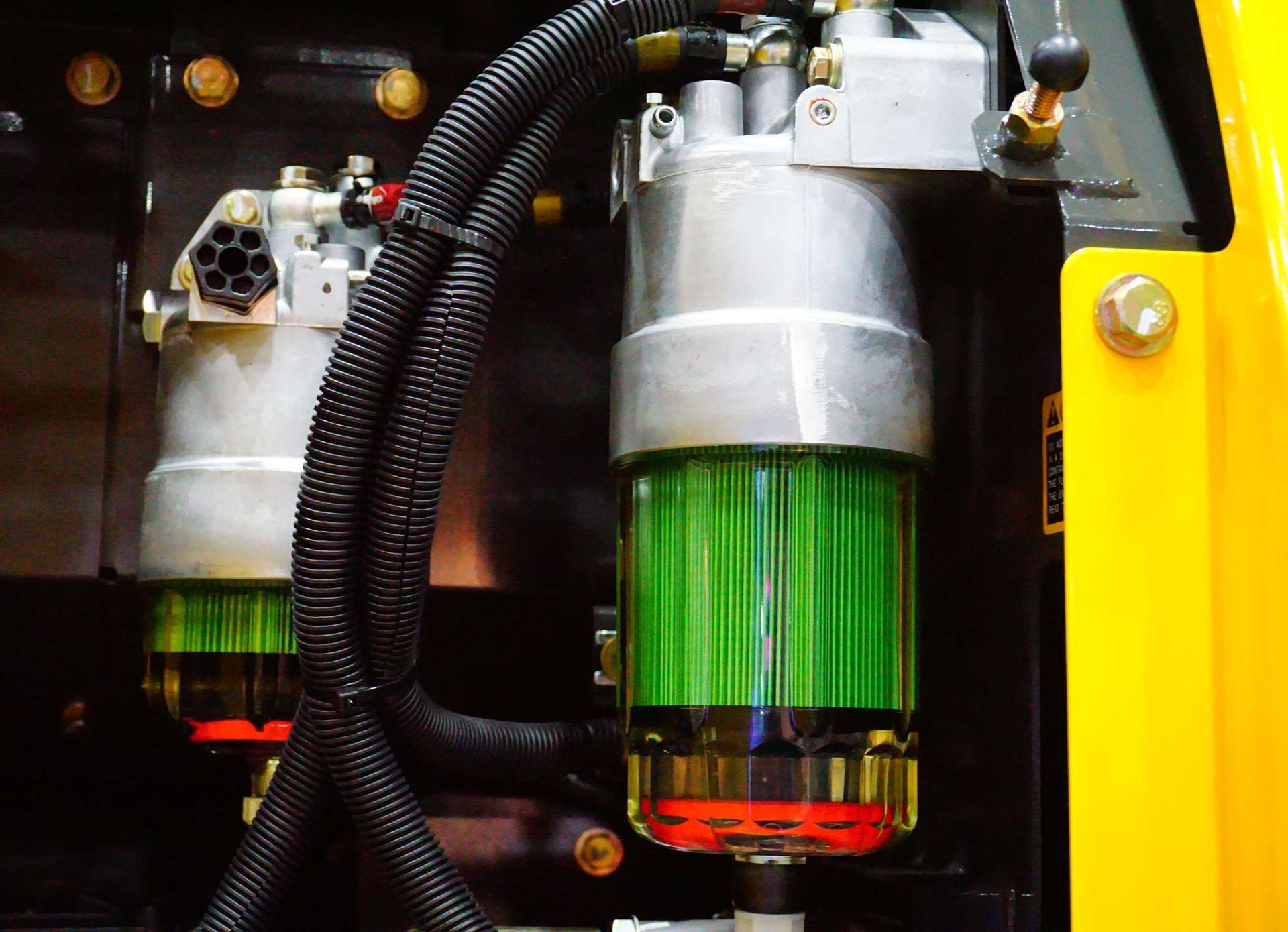

The specifications of our new oil flushing and filtration module are as follows: 144-1000ltr/pm 33 barg diesel-driven pumping system complete with 12kw heating package ensures the Reynolds No meets or exceeds 4000 pending pipes inside diameter Directional control valves with reverse flow capabilities 5 Micron filtration package 100 Mesh screens Custom control panel that provides real-time flow, pressure, and filter condition ISO 4406 particle count and temperature monitoring.

New Products

Introducing our new Lubemaster OS600, which is EXD Zone 1 compliant and can be operated in live process areas, including offshore oil and gas platforms.

Other Services

In addition to our oil flushing and filtration services, we provide comprehensive analysis on all compartments, including engine and hydraulic oil testing, gearboxes, differentials, turbines, compressors, grease, and coolant. We offer the following services:

- Mechanical servicing of a fleet of offshore-based compressors

- Programmed maintenance of training site facilities in Gippsland for one of our major clients

- Self-contained oil flushing and filtration modules in Sale

- Onsite oil cleaning and decontamination services Line flushing by our highly skilled personnel in our mobile unit

- Customized maintenance programs for your equipment to suit your exact requirements and budget

- Our commitment to quality and customer satisfaction is evident in all of our services.

- We have the resources to manage your project on time and on budget with our highly skilled team of project managers and dedicated personnel.

For more information about our oil flushing and filtration services or to schedule an appointment with our experts, please contact us at

03 5144 5733 or email us at

info@unionhyd.com.au.

OIL TESTING

Our company offers a comprehensive analysis service for all compartments, including engine and hydraulic oil testing, gearboxes, differentials, turbines, compressors, grease, and coolant.

Our process includes the following steps:

- Delivery of an oil sampling kit to your location

- Detailed instructions for collecting and submitting oil samples

- Professional analysis of the oil samples in our laboratory

- Comprehensive reporting of the analysis results

This service allows us to provide our customers with valuable insights into the condition of their equipment, enabling them to make informed decisions about maintenance and repair needs.

For self-contained oil flushing and filtration modules in Sale, call the hydraulics specialists at Union Hydraulics today on

03 5144 5733.

Browse our website

Our service location

We are locally based in Sale Regional Victoria, with Services throughout Melbourne, Victoria, Interstate & & Overseas. For hydraulic & pneumatic systems. Along with our High-Tech, Self-Contained Oil Flushing Filtration unit for remote site operations.

Contact Information

Phone: 03 5144 5733

Business fax number: 03 5144 7766

Email: sales@unionhyd.com.au

Address: 316-322 Raglan Street, Sale VIC 3850